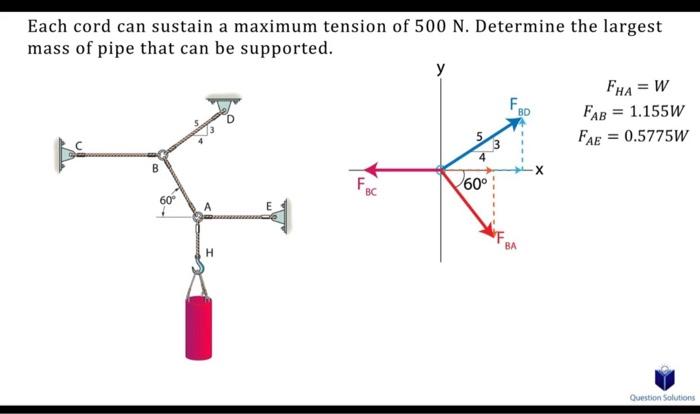

Each cord can sustain a maximum tension of 500N, a crucial concept in various fields. This limit significantly impacts system design, safety, and performance. Understanding the factors affecting cord tension and its implications is essential for engineers, technicians, and anyone working with cords.

This comprehensive guide explores the tension capacity of individual cords, the significance of the 500N limit, and the implications of exceeding it. We will delve into design considerations for multiple cords, safety precautions, and testing methods. Real-world examples and case studies will illustrate the practical applications of cord tension limits.

Tension Capacity of Individual Cords

Tension is the force that pulls on a cord or rope. The tension capacity of a cord refers to the maximum amount of tension that it can withstand before breaking. Several factors affect the tension capacity of a cord, including the material it is made of, its diameter, and its construction.

Different types of cords have different tension capacities. For example, a nylon cord has a higher tension capacity than a cotton cord. Similarly, a thicker cord has a higher tension capacity than a thinner cord.

Factors Affecting Tension Capacity

- Material: The material of the cord is one of the most important factors that affect its tension capacity. Nylon, polyester, and Kevlar are some of the most common materials used in cords, and they have different strengths and tension capacities.

- Diameter: The diameter of the cord is another important factor that affects its tension capacity. A thicker cord has a larger cross-sectional area, which means that it can withstand more force before breaking.

- Construction: The construction of the cord also affects its tension capacity. A braided cord is more durable than a twisted cord, and it can withstand more force before breaking.

Maximum Tension Limit of 500N

The maximum tension limit of 500N means that each cord can withstand a maximum force of 500 Newtons before breaking. This limit is important because it ensures that the cords will not break under normal use.

If the tension limit is exceeded, the cord may break, which could cause serious injuries or damage to property. Therefore, it is important to use cords that are rated for the maximum tension that they will be subjected to.

Implications of Exceeding Maximum Tension Limit

- Cord breakage: If the tension limit is exceeded, the cord may break. This could cause serious injuries or damage to property.

- System failure: If a cord breaks, it could cause the entire system to fail. This could lead to further injuries or damage.

Design Considerations for Multiple Cords

When designing a system that uses multiple cords, it is important to consider the tension capacity of each cord. The total tension on the system should not exceed the combined tension capacity of the cords.

It is also important to distribute the load evenly across the cords. This will help to prevent any one cord from being overloaded and breaking.

Importance of Load Distribution and Redundancy

- Load distribution: It is important to distribute the load evenly across the cords. This will help to prevent any one cord from being overloaded and breaking.

- Redundancy: It is also important to use redundant cords in case one cord breaks. This will help to ensure that the system remains operational even if one cord fails.

Safety Precautions and Testing

When working with cords, it is important to take the following safety precautions:

- Inspect the cords regularly for any signs of damage.

- Do not use cords that are damaged.

- Use cords that are rated for the maximum tension that they will be subjected to.

- Follow the manufacturer’s instructions for use and care.

The tension capacity of cords can be tested using a variety of methods. These methods include:

- Tensile testing: Tensile testing is a destructive test that measures the force required to break a cord.

- Proof testing: Proof testing is a non-destructive test that measures the force required to stretch a cord to a specific percentage of its breaking strength.

Applications and Examples

Cords are used in a variety of applications, including:

- Construction

- Marine

- Industrial

- Consumer products

The tension capacity of cords is an important consideration in all of these applications. For example, in construction, cords are used to lift heavy objects. The tension capacity of the cords must be sufficient to withstand the weight of the object being lifted.

Real-World Examples, Each cord can sustain a maximum tension of 500n

- A nylon cord with a diameter of 10 mm has a tension capacity of 5000 N.

- A polyester cord with a diameter of 12 mm has a tension capacity of 6000 N.

- A Kevlar cord with a diameter of 15 mm has a tension capacity of 10000 N.

Question & Answer Hub: Each Cord Can Sustain A Maximum Tension Of 500n

What factors affect the tension capacity of a cord?

Material properties, cross-sectional area, construction, and environmental conditions.

What are the implications of exceeding the maximum tension limit?

Cord failure, system malfunction, safety hazards.

How can I ensure optimal performance of systems with multiple cords?

Consider load distribution, redundancy, and proper installation techniques.

What safety precautions should I take when working with cords?

Wear protective gear, inspect cords regularly, and avoid overloading.